CHALLENGE

- Delivering even cooler cars as fast as possible and getting them right the first time without going over time or budget

- Creating more interesting and intricate parts that are hard to mock up, need to fit existing body panels, or are impossible to do by hand

- Reducing time spent doing trial and error (building it, fixing it, tweaking it)

SOLUTION

- Geomagic® Design X™ scan-to-CAD software by 3D Systems

- Geomagic® Control X™ inspection software by 3D Systems

- FARO® Design ScanArm

RESULTS

- Enabled engineers to be more creative and flexible and build even cooler parts free form that often wouldn’t have been possible before.

- Created better-fitting, higher-quality parts in one try—with no paint scratching.

- Saved days’, weeks’, and sometimes months’ worth of work, improved delivery time, and reduced labor costs.

- Created CAD files that they could trust with high-resolution scan data.

- Streamlined design by forgoing other CAD software.

Dave Kindig's artwork

Metal fabricator Greg Hebard in a 1957 Corvette

Engineer Will Lockwood in front of a 1963 split-window Corvette

Kindig-It Design in Salt Lake City, Utah, is a high-end, custom automotive shop with a team of artists and fabricators who specialize in restomod—they’ve been restoring a broad range of vehicles and modifying them to be more modern since 1999. We’re talking super high-end work with very clean lines and an almost race-car level of sophistication. Tight-fitting form, functional, high-end cars. Everything they do is custom, bespoke.

Known for their TV show on the Discovery Channel’s Motor Trends network—which airs worldwide and gives a behind-the-scenes look at their process for building some super cool cars—their current lead time is about three to four years, so get in line.

Owner Dave Kindig has been designing cars by hand since he was a kid. “If they want to go over the top, I'm definitely their guy,” says Dave.

Dave Kindig on his showroom floor

He adds, “And what's great is that the guys back there, Greg and Will, take my hand-rendering and use Geomagic Design X to take all of the information that we've gathered off of the FARO ScanArm and put it into the computer, which is a game changer.” Now they can go from design concept all the way through CAD design and 3D printing. When Dave first started playing with hot rods in the 1990s, it was impossible to do the things they are doing now.

Greg Hebard has been a metal fabricator at Kindig-It since 2014, and is transitioning into more digital work including scanning, reverse engineering, 3D printing, and CNC programming. Greg says that one of the coolest parts about working at Kindig-It is talking to Dave, hearing his ideas, and turning those ideas into reality. “Dave is a perfectionist. All the tolerances for the door gaps, the trim, everything has to be really perfect,” says Hebard. “And when I use Geomagic Design X and the FARO ScanArm to do that, I can really nail it and make parts that are going to be perfect.”

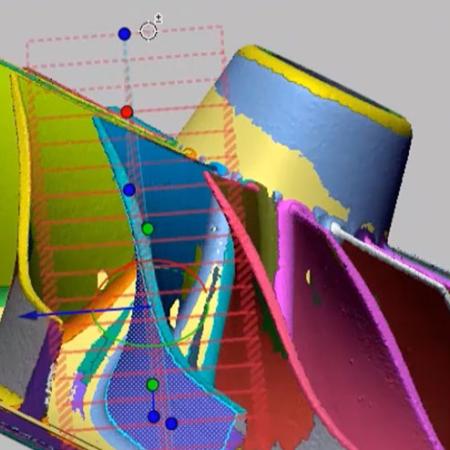

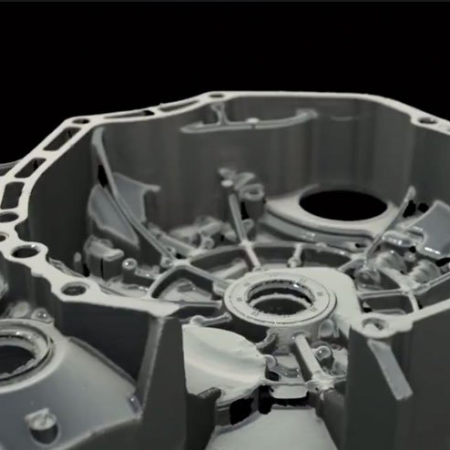

Engineer Will Lockwood has been at Kindig-It since 2003 and started building customs when he was 16. Ultimately, Will’s job is to take Dave's drawings off the wall and do whatever it takes to make them into a real car. To do that, Kindig-It increasingly uses reverse engineering for a variety of applications ranging from designing new trim, body, and engine components to recreating components you can no longer buy or find. Since they started using Geomagic Design X and the FARO Design ScanArm in 2018, Kindig-It has used reverse engineering for all kinds of projects, from headlights, taillights, and engine intakes, to trim pieces, scoops, and window openings. Most of the car parts they use reverse engineering for are 3D printed.

Getting More Creative and Building Cooler Parts and Cars

One of the things that sets Kindig-It Design apart is that they get to use their creativity to make cool cars and parts even cooler.

Basically, Dave only has to tell Greg and Will what he wants and they can start building cool stuff three-dimensionally, looking at it and knowing that it's actually going to fit the vehicle. “It's a no-brainer,” says Dave. “We’ve got creativity here, the right equipment to do it, and, of course, the right guys to do it.”

What both Greg and Will like about working at Kindig-It is the ability to be more creative and artistic. “I like designing things and I like working with metal. And this is the best platform to do that. We have more artistic freedom to work our craft and really go all out on projects,” says Greg.

Pushing boundaries, doing the most with the time that they have, and making nicer cars is what they’re ultimately after. “We want to exude our art on these cars. Geomagic Design X and the FARO ScanArm scanning capabilities have just exponentially increased that for us. And it's a huge value, not only in dollars and cents, but in our enjoyment of the process,” adds Will.

“We've always built cool stuff. But now, with the added technology, we're building even cooler stuff—in a lot less time.”—Dave Kindig, Owner, Kindig-It Design, Salt Lake City, Utah, USA

“The coolest thing for me that’s changed my whole life entirely is not having to stick to a two-dimensional world, which means now we can actually dream in 3D and I can basically live in 3D Land; and it's amazing. You know it's going to fit. It just pays off dividends.”—Will Lockwood, Engineer, Kindig-It Design, Salt Lake City, Utah, USA

“Everything that I've scanned using the FARO ScanArm and reverse engineered in Geomagic Design X, I've printed it and it has fit the car perfectly every time.”—Greg Hebard, Metal Fabricator, Kindig-It Design, Salt Lake City, Utah, USA

Using X-Ray Vision: Better-Fitting, Higher-Quality Parts in One Try

Building custom vehicles is a bit tricky because everything's one-off. At Kindig-It Design, there’s no time to do something twice. Every project is an experiment that has to be right the first time. So, every prototype they make is the final part—basically, they’re a prototype shop without revisions.

Designing and fabricating a part for a finished car by hand that fits and doesn’t scratch the paint is not only a time-consuming chore of trial and error, it’s also stressful. Because the fit and finish on the cars needs to be perfect, using the FARO Design ScanArm and Geomagic Design X to design trim pieces takes the guess work out and allows Greg and Will to create parts that fit perfectly to a painted surface on the first try without too much effort, which saves a lot of time.

“It helps us improve our delivery time. It helps us be creative. It basically has become our X-ray vision.”—Will Lockwood, Engineer, Kindig-It Design, Salt Lake City, Utah, USA

For example, in the past, they dealt with under-hood components that didn't fit because, once the hood is shut, you can't see what the clearances are. Now they can scan the engine bay and hood with the ScanArm; assemble them together and close the hood virtually in Geomagic Design X; and then see what space constraints they actually have to deal with to make sure that there's clearance under the hood. “It's our X-ray vision,” Will concludes.

In addition, they had chopped the car, so he had to have custom glass made for the windows. The window openings were pretty tricky. After a failed attempt to do it non-digitally, Will scanned the window opening to get the dimensions, provided that information to the glass company, and he got back glass that fit perfectly.

Check out this blue 1967 Dodge Coronet in season five of the show.

Saving Time and Reducing Labor Costs

Since they started using the FARO Design ScanArm and Geomagic Design X at Kindig-It Design, they’ve saved days’, weeks’, and sometimes months’ worth of work, improved delivery time, and reduced labor costs by taking the guesswork out and eliminating trial and error. “We're creating stuff in a few days that would have taken us months and months to do before. Having all of the cool tools has made it so much quicker,” confirms Dave.

According to Will, some of the biggest challenges they face in the custom auto business are timeline and budget. Geomagic Design X and the FARO ScanArm have cut the time by at least half, depending on the project—freeing up time to innovate.

“In some cases, it's saving days’ worth of work. It would take maybe two weeks to hand-make a piece of trim. But if I can scan it and get it in the computer, it might take me a day and a half. And it's just invaluable,” adds Greg.

For example, the intake pipe that Greg built for the 1966 Chevy Nova would have taken him about a week to manufacture in a traditional way by hand, and it would have been a real chore. But, by scanning it and reverse engineering the engine bay in Geomagic Design X, he was able to do it in about a day. And he built the trim for the 1971 Karmann Ghia in about two weeks using reverse engineering and 3D printing, which would have taken him months to do by hand.

Streamlining the Design Process

Since they started using reverse engineering, Greg and Will have been able to streamline design. “What I've really found is that every time I touch it, every time I use the FARO ScanArm and the Geomagic Design X software, it's a game changer for me. And, exponentially, I'm just so much happier and so much more productive,” says Will. “It's fun to watch. And then it's fun to look back and realize the difference that the software and the scanning ability has made to our process and, overall, our art. I'm still kind of blown away by the whole deal.”

He adds that a lot of the fans of the show might just think it’s magic how they’re using the scanner to make parts. “When they see the scanning on the show, they think it's pretty cool.”

Taking Design to the Next Level: Geomagic Design X

Another way Greg and Will have been able to streamline design is by forgoing other CAD software and modeling everything in Geomagic Design X. “I thought I'd be importing things into SOLIDWORKS, but I really haven't. I just go with Geomagic Design X the entire time,” notes Greg.

Both Greg and Will found Geomagic Design X easy to use right out of the gate. “I had a little bit of help from some of the application engineers at 3D Systems. I'd say probably 12 hours total and I was using Geomagic like I had been using it for years,” recalls Greg. And he really liked that 3D Systems used actual projects from Kindig-It Design during the training, so it was tailored to their workflow.

“I would absolutely recommend a FARO ScanArm and Geomagic Design X to any shop. I'd never want to be without it,” says Will. Dave adds, “I feel kind of bad for some of the competition because they don't have the same equipment. Maybe they should because it's a game changer for us.”

“It's kind of unreal what we're able to accomplish here when you see these finished cars. They're next-level. They're really cool.”—Greg Hebard, Metal Fabricator, Kindig-It Design, Salt Lake City, Utah, USA

Looking Towards the Future

“Ultimately, if Dave would let me, I would scan these entire cars. They would absolutely be entirely virtually built in the computer before we even touched them. One day, that will happen,” predicts Will.

“There is nothing that we can't build at this point. If we can dream it, we can build it. Quite literally, within a couple of hours, I have it ready to go,” concludes Dave.

"I feel a lot better about the day," Dave Kindig in his 1957 Corvette